Ultrasonic Cleaners in the Healthcare Industry: Applications and Benefits

2025-11-24

Ultrasonic cleaners have revolutionized the way medical and dental instruments are cleaned and sterilized, providing a highly efficient and effective solution for healthcare settings.

Ultrasonic cleaners have revolutionized the way medical and dental instruments are cleaned and sterilized, providing a highly efficient and effective solution for healthcare settings. This article explores the workings of ultrasonic cleaners, their key applications in healthcare, and the benefits they offer in improving hygiene, safety, and operational efficiency. It also discusses what to look for when choosing an ultrasonic cleaner and the future trends in ultrasonic cleaning technology for healthcare in 2025.

What is an ultrasonic cleaner in healthcare?

-What is the difference between an autoclave and an ultrasonic?

-Why is an ultrasonic cleaner important in healthcare?

How do ultrasonic cleaners work?

-What is the working principle of ultrasonic machine?

-What is the process of ultrasonic cleaning?

-What are the features of ultrasonic cleaner?

Key applications of ultrasonic cleaners in healthcare

-Ultrasonic cleaner for dental instruments

-Laboratory ultrasonic cleaner

-Ultrasonic eyeglass cleaner

Benefits of Ultrasonic Cleaners in Healthcare

What should I look for in an ultrasonic cleaner?

Future trends in ultrasonic cleaning for healthcare 2025

What is an Ultrasonic Cleaner in Healthcare?

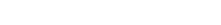

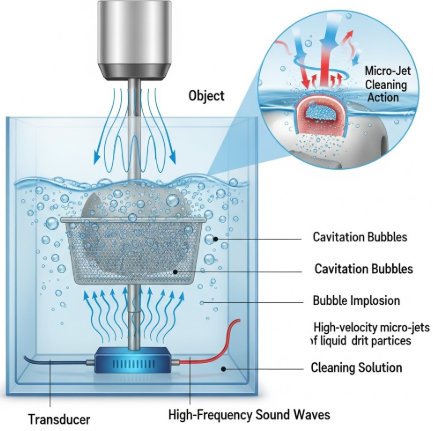

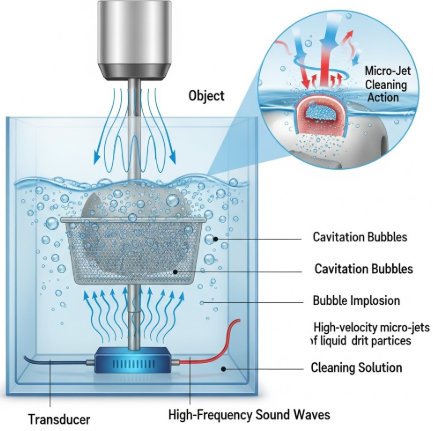

Ultrasonic cleaners are advanced cleaning devices that utilize high-frequency sound waves to clean medical instruments, devices, and other equipment. These devices work by generating ultrasonic waves (typically in the range of 20-400 kHz) that create microscopic bubbles in a cleaning solution. The process of cavitation—the rapid formation and collapse of these bubbles—effectively removes dirt, debris, biofilms, and contaminants from surfaces, even those with intricate designs or hard-to-reach areas.

What is the Difference Between an Autoclave and an Ultrasonic Cleaner?

While both autoclaves and ultrasonic cleaners are used in healthcare for sterilization and decontamination, they work in fundamentally different ways:

1.Autoclaves: These machines use steam under high pressure to sterilize instruments. The process involves high temperatures (usually 121–134°C) that kill bacteria, viruses, and spores. However, autoclaves may not effectively clean instruments with intricate details, especially where debris may be lodged in crevices.

2.Ultrasonic Cleaners: Unlike autoclaves, ultrasonic cleaners use high-frequency sound waves and cavitation to physically clean the surface of medical instruments. They don’t sterilize in the traditional sense but are highly effective at removing debris, bacteria, and organic material before sterilization, ensuring that instruments are properly prepared for the next steps in the sterilization process.

Why is an Ultrasonic Cleaner Important in Healthcare?

Ultrasonic cleaners are indispensable in healthcare for several reasons:

Thorough Cleaning: They reach areas that are difficult to clean manually, such as joints, hinges, and grooves of medical instruments. This ensures that instruments are thoroughly decontaminated, reducing the risk of cross-contamination.

1.Time Efficiency: Ultrasonic cleaners significantly speed up the cleaning process, allowing healthcare facilities to process more instruments in less time.

2.Enhanced Safety: The ultrasonic cleaning process reduces the risk of accidental injury to staff members since it is a hands-free cleaning method. It also prevents damage to delicate instruments by cleaning them more gently compared to traditional methods.

How Do Ultrasonic Cleaners Work?

What is the Working Principle of Ultrasonic Machines?

The working principle of an ultrasonic cleaner is based on cavitation. When ultrasonic waves pass through a liquid, they generate pressure waves that create microscopic bubbles in the solution. These bubbles form and collapse at an extremely high frequency, producing a scrubbing effect on the surface of the objects being cleaned. This process removes dirt, oils, and other contaminants, making it highly effective for cleaning complex or delicate instruments.

What is the Process of Ultrasonic Cleaning?

The ultrasonic cleaning process generally follows these steps:

1.Preparation: Instruments are placed in the cleaning tank, which is filled with a suitable cleaning solution. The solution may vary based on the type of instrument and the nature of the contaminants.

2.Cavitation: The ultrasonic transducers emit high-frequency sound waves, creating tiny bubbles in the cleaning solution. These bubbles form and collapse around the surfaces of the items in the tank.

3.Cleaning: As the bubbles collapse, they create small shockwaves that remove debris and contaminants from the instruments, even from hard-to-reach areas. The process is gentle, ensuring no damage to the instruments.

4.Rinsing: After the ultrasonic cleaning cycle is complete, the items are usually rinsed to remove any remaining cleaning solution.

5.Drying: The instruments are dried, either through air drying or using a specialized drying function in the ultrasonic cleaner.

What Are the Features of Ultrasonic Cleaners?

Ultrasonic cleaners typically come with the following features:

1.Adjustable Frequency and Power: These settings allow customization depending on the type of instrument and the level of contamination.

2.Heated Tanks: Many ultrasonic cleaners have built-in heaters that can increase the temperature of the cleaning solution, improving the efficiency of the cleaning process.

3.Timer Settings: Ultrasonic cleaners allow operators to set specific cleaning times, ensuring consistent cleaning results.

4.Cleaning Basket: A removable basket to hold instruments securely while allowing the ultrasonic waves to reach all surfaces.

5.Digital Controls: Modern ultrasonic cleaners often come with digital controls for easy operation and precise settings.

Key Applications of Ultrasonic Cleaners in Healthcare

Ultrasonic Cleaner for Dental Instruments

In dental practices, ultrasonic cleaners are essential for thoroughly cleaning dental tools such as scalers, probes, and root canal instruments. These instruments often have complex shapes with tiny crevices where bacteria and debris can accumulate. The ultrasonic cleaning process ensures that even the smallest particles are removed, reducing the risk of infection during dental procedures.

Laboratory Ultrasonic Cleaner

In medical laboratories, ultrasonic cleaners are used to clean test tubes, glassware, petri dishes, and other delicate instruments. The high-frequency cavitation cleans biological samples and residues effectively, without damaging the equipment. This ensures accurate results and maintains the integrity of laboratory tools.

Ultrasonic Eyeglass Cleaner

Eyeglasses and other optical equipment can be effectively cleaned using ultrasonic cleaners. These devices remove dust, oils, and debris from lenses and frames without scratching or damaging the delicate surfaces. Regular cleaning with ultrasonic technology helps maintain the clarity and condition of optical devices.

Benefits of Ultrasonic Cleaners in Healthcare

1. Thorough and Effective Cleaning

Ultrasonic cleaners are highly efficient at removing contaminants that manual cleaning methods might miss. The cavitation process reaches into small crevices, joints, and other hard-to-reach places, ensuring that instruments are thoroughly cleaned.

2. Time and Labor Efficiency

Compared to manual cleaning, ultrasonic cleaning is significantly faster, which helps healthcare providers improve operational efficiency. It allows healthcare staff to clean large batches of instruments at once, reducing the time and labor required.

3. Enhanced Patient Safety

By effectively cleaning medical instruments before sterilization, ultrasonic cleaners help prevent cross-contamination and reduce the risk of infection. This is crucial in healthcare environments where infection control is of utmost importance.

4. Reduced Risk of Instrument Damage

Ultrasonic cleaning is a gentle yet effective process that is less likely to cause damage to delicate instruments compared to manual cleaning, which may involve abrasive brushes or harsh chemicals.

5. Eco-Friendly and Cost-Effective

Ultrasonic cleaners use water-based cleaning solutions, reducing the need for harsh chemicals. They also reduce the need for disposable cleaning materials, making them an environmentally friendly option. Over time, their efficiency also leads to cost savings by reducing labor and material costs.

What Should I Look for in an Ultrasonic Cleaner?

When choosing an ultrasonic cleaner for healthcare purposes, consider the following factors:

1.Capacity: Ensure that the ultrasonic cleaner is large enough to handle the volume of instruments in your facility.

2.Power and Frequency: Choose a model with adjustable power and frequency settings to tailor the cleaning process to your specific needs.

3.Durability: Look for models made with high-quality materials that can withstand the demands of a busy healthcare environment.

4.Ease of Use: Digital controls, timer settings, and easy-to-read displays make the cleaner user-friendly.

5.Safety Features: Features such as overheat protection and automatic shutoff ensure safe operation.

Future Trends in Ultrasonic Cleaning for Healthcare (2025)

The future of ultrasonic cleaning in healthcare looks promising, with several trends expected to shape the industry by 2025:

1.Smart Technology Integration: Ultrasonic cleaners will become more intelligent, with features like automated cleaning cycles, real-time monitoring, and cloud-based data storage for better tracking and reporting.

2.Miniaturization and Portability: As healthcare facilities become more mobile and decentralized, ultrasonic cleaners are likely to become more compact and portable, allowing easy use in various environments.

3.Advanced Cleaning Solutions: The development of more effective, biodegradable, and non-toxic cleaning agents will enhance the ultrasonic cleaning process, making it even more efficient and environmentally friendly.

4.Automation: The integration of robotic systems and automation in ultrasonic cleaning processes will increase efficiency, reduce human error, and improve the consistency of cleaning results.

Conclusion

Ultrasonic cleaners have become an indispensable tool in the healthcare industry, offering unparalleled cleaning efficiency and effectiveness. From dental practices to medical laboratories, these devices help ensure that instruments are thoroughly decontaminated, improving patient safety and reducing the risk of infection. With ongoing advancements in technology, ultrasonic cleaning systems are set to become even more efficient, cost-effective, and environmentally friendly in the coming years. As healthcare continues to evolve, ultrasonic cleaners will play a crucial role in maintaining high standards of hygiene and safety.

Recommended Reading:

1.Top 5 Best Ultrasonic Cleaners for Dental Instruments: Effective Cleaning Solutions

2.Ultrasonic Glasses Cleaner :The Complete Guide to Cleaning Your Eyeglasses

3.Why Choose the GT-X3 Ultrasonic Dental Cleaner for Your Practice