|

Industry Focus

|

Aerospace, semiconductor, healthcare, general manufacturing

|

Aerospace, automotive, electronics, medical, jewelry, laboratory

|

Heavy industry (automotive, manufacturing, aerospace)

|

Industrial manufacturing, medical devices, R&D labs

|

Labs, watchmaking, electronics, medical instruments

|

|

Product Range

|

Benchtop → fully automated lines; dual-frequency, solvent handling

|

Benchtop → large industrial immersion & spray-wash; multi-tank skids

|

Industrial-scale tanks, rinsing stations, robotic part-handling options

|

Washer-disinfectors, benchtop & industrial; automation-ready units

|

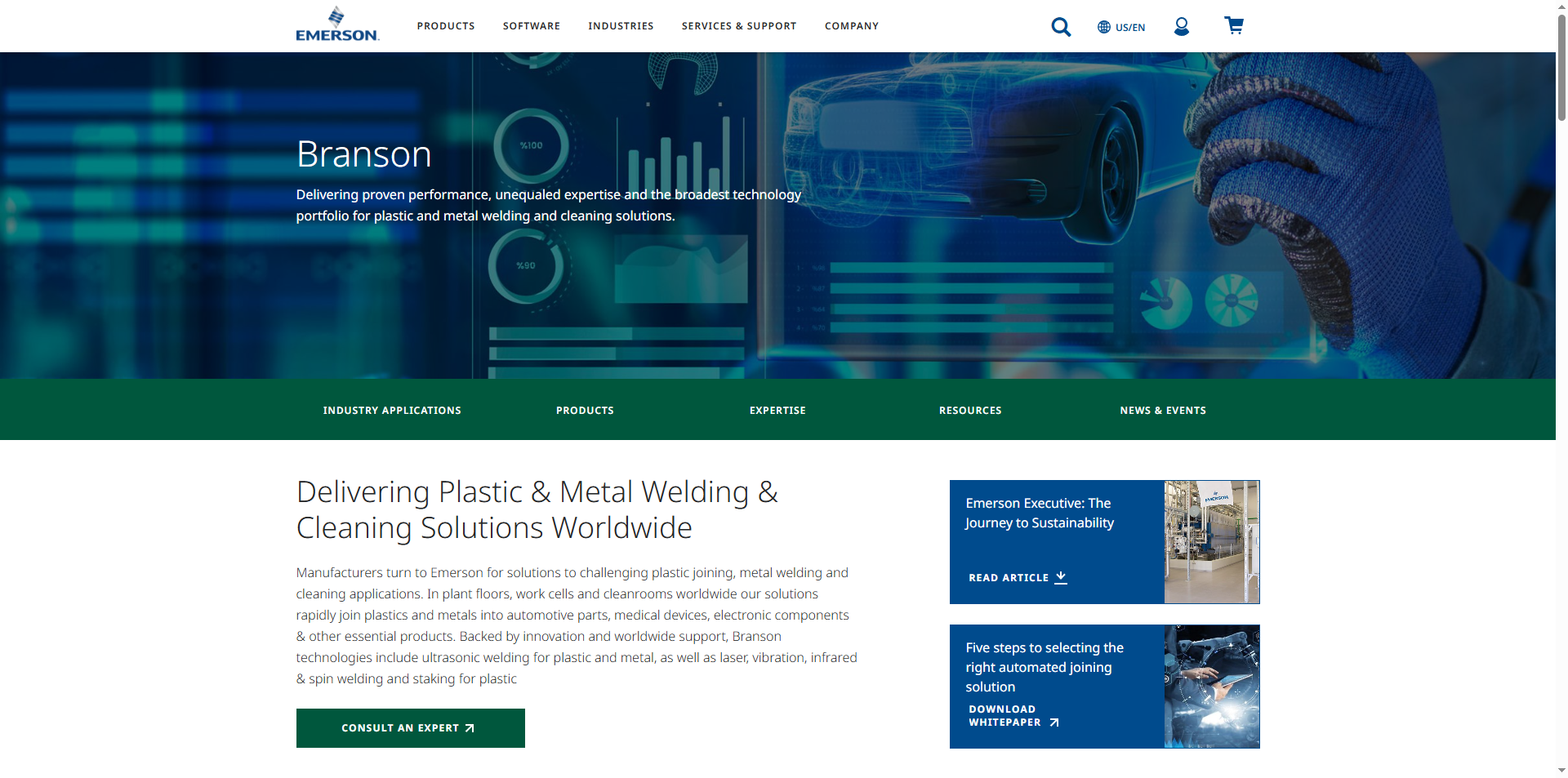

Compact benchtop units → large-format heated & filtered recirculation tanks

|

|

Key Technologies

|

Proprietary generators & transducers; precise frequency control

|

Precision-tuned transducers; digital frequency control; IoT monitoring

|

Closed-loop EcoCycle filtration; rugged industrial-grade generators

|

Automated degassing; SterileWave™ for compliant sterilization; validation kits

|

Multi-frequency operation; digital touch-screen controls; low-noise design

|

|

Customization Options

|

Tank size/power, filtration, solvent handling, custom manifolds

|

Skid-mounted multi-tank lines; custom baskets, fixtures, control logic

|

Modular stations; add-on rinse modules or robots

|

PLC/robotic integration; tailored validation protocols

|

Custom accessory bundles (baskets, heaters, filters); special-purpose formulations

|

|

Sustainability Focus

|

Water- & detergent savings via power modulation

|

Closed-loop filtration; energy-efficient generators; minimal chemical waste

|

Water-based detergents; closed-loop recirculation

|

Emphasis on process validation to reduce chemical overuse

|

–

|

|

Automation & IoT

|

Semi-automated fill/drain; optional conveyor integration

|

IoT-enabled monitoring; smart controls & alarms

|

Robotic loading, PLC controls

|

Seamless integration with conveyors/robots; WashGuard compliance software

|

Limited (focus on precision benchtop rather than full automation)

|

|

Regulatory Support

|

IQ/OQ/PQ documentation; ISO, CE, FDA

|

IQ/OQ/PQ documentation; global CE/FDA/ISO compliance

|

–

|

FDA/AAMI/ANSI validation support

|

CE marking; built-in process repeatability

|

|

Global Service Network

|

Worldwide service centers; preventive-maintenance contracts

|

Offices & certified technicians in 50+ countries; rapid spare-parts delivery

|

North America–focused, with robust U.S. support

|

Emerson’s global infrastructure for parts, calibration, training

|

Germany-based engineering; distribution partners in 80+ countries

|